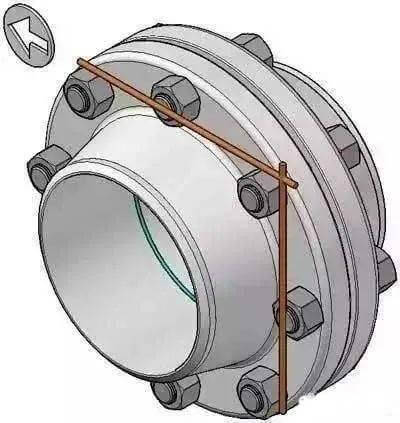

Tightening flange bolts is one of the common operations in many engineering projects. So how to tighten flange bolts scientifically and standardly is a very important issue. Below, Aeroboom will introduce in detail how the flange bolts are tightened scientifically.

Fastening Technical Requirements for Installation of Equipment and Pipeline Flanges

(1) Inspection of Flange Fasteners

1 Gasket: When installing, make sure the gasket is new, clean and dry, and inspect the gasket for defects and damage. Old gaskets cannot be reused. Before installation, make sure that the size and grade of the gasket used are consistent with the flange identification.

2 Flange: Check the flange face for damage such as scratches, nicks, mud, corrosion and burrs before installation. When the dents and scratches radially passing through the waterline of the flange sealing surface exceed 0.2mm, and the coverage exceeds half the width of the gasket sealing surface, the flange must be replaced or the sealing surface must be reworked and repaired. The position of the nut support surface on the back of the flange should be parallel and smooth. Check flange alignment.

3 Bolts and nuts: Check whether the bolts and nuts are used correctly according to the equipment and piping design requirements. Threads and contact surfaces must be free of dirt, rust, heavy skin, nicks, burrs, chips and other foreign substances that affect torque during tightening. Repair of bolts by welding or machining is not permitted. After the flange is installed and tightened, at least two threads are exposed outside the nut. The bolts and nuts must be lubricated before use, so that the bolts have a low friction coefficient and improve the anti-slip and anti-corrosion properties of the bolts and nuts. Stud threads, nut threads and contact surfaces must be degreased and dry before lubricating. A uniform lubricant should be properly used for bolt threads, nut threads, nut bearing surfaces, washers, and nut bearing surfaces on flanges. Use high-temperature anti-seize as needed.

(2) Faste ning Method of Flange Bolts

Torque-free Torque wrench or hammer wrench, suitable for general equipment and pipeline flange tightening, can be selected according to bolt size and flange pressure level. The tightening requirements are as follows:

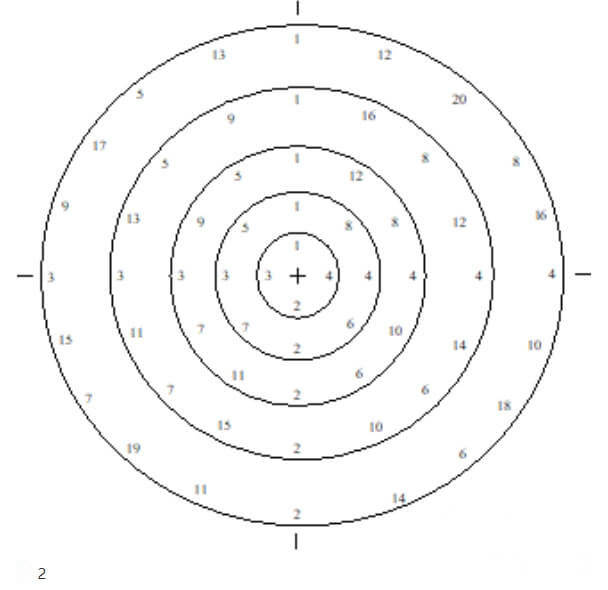

1 Formulate a tightening plan, tighten the flange symmetrically, and the order of tightening is numbered as shown in the figure below.

2 Position the gasket with 4 bolts at positions 1, 2, 3, 4, making sure that the centre of the spiral wound gasket is within the flange edge.

3 Hand-tighten the set bolts, then insert other stud bolts and hand-tighten to balance the load, making sure that at least 2 threads are exposed on each end of the nut.

4 According to the field equipment and flange, one tightening cycle is calculated as one time, and the number of tightening (at least 3 times) and the hammer load (strength) for each tightening should be reasonably determined. The tightening hammer load (strength) is tightened in order from small to large (such as 50%, 80%, 100% increments). Do not apply the load too fast or too large to prevent the gasket seal from failing.

5 The sequence of each tightening of the torque less Torque wrench or hammer wrench: Tighten two diametrically opposite bolts to the predetermined hammer load (strength) of the bolts. Tighten another pair of bolts approximately 90 degrees circumferentially apart from the previous two bolts. Continue tightening until all remaining bolts are tightened to the specified hammer load.

6 Finally, tighten all bolts clockwise or counter-clockwise with 100% hammer load (strength).

(2) Hydraulic Torque Wrench: suitable for important equipment and pipeline flanges such as high temperature and high pressure, flammable and explosive.

The tightening requirements are as follows:

1 Formulate a tightening plan, formulate an appropriate torque, and conduct a design review according to parameters such as bolt strength, initial sealing specific pressure of gasket, working sealing specific pressure, medium pressure, etc., to prevent bolt breakage and seal failure caused by the loss of elasticity of the gasket due to excessive compression force.

2 Formulate a tightening plan, tighten the flange symmetrically, and the order of tightening is as shown in the figure above.

3 Position the gasket with 4 bolts at positions 1, 2, 3, and 4, making sure that the centre of the spiral wound gasket is within the flange edge.

4 Hand-tighten the set bolt, then insert the other stud bolts and hand-tighten it to balance the load, making sure that at least 2 threads are exposed on each end of the nut.

5 According to the field equipment and flange, one tightening circle is calculated as one time, and the number of tightening times (at least 3 times) and the tightening torque each time should be reasonably determined. The tightening torque is tightened in order from small to large (such as 50%, 80%, 100% increments). Do not apply the load too fast or too large to prevent the gasket seal from failing.

6 The sequence of each tightening of the torque wrench: tighten the two diametrically opposite bolts to the specified torque of the bolts. Tighten another pair of bolts approximately 90 degrees circumferentially apart from the previous two bolts. Continue tightening until all remaining bolts are tightened to the specified torque.

7 Finally, tighten all bolts clockwise or counter-clockwise to 100% torque.

8 Record the torque value for reference in future maintenance.

(3) Bolt tensioner: suitable for high temperature and high pressure, flammable and explosive and other important equipment and pipeline flanges. The tightening requirements are as follows:

1. Formulate the fastening plan, formulate the appropriate tensile force, and conduct the design review according to the bolt strength, the initial sealing specific pressure of the gasket, the working sealing specific pressure, the medium pressure and other parameters, to prevent bolt breakage and seal failure caused by the loss of elasticity of the gasket due to excessive compression force.

2 When the bolt tensioner stretches and tightens the bolts individually (step by step), the principle of bolt tightening uniformity shall be followed. Refer to the torque wrench tightening sequence for tension and tightening.

3. During the tension and tightening process of the bolt tensioner, the number of times of stretching and tightening should be reasonably determined, and the pressure should be applied in order from small to large (such as 50%, 80%, 100%), and the pressure should be uniform. Each time a certain pressure is increased, it must be stabilized and then increased to avoid excessive impact tension and effect to the pre-tightening effect of the bolt.

4 Record the pressure value for reference for future maintenance.

Thermal Fastening Requirements for Equipment and Pipeline Heating

Hot Tightening According to the Temperature in Table 1

1 Hot and cold fastening temperature of equipment and pipelines. Unit: °C

| Operating temperature | One hot tightening, cold tightening temperature | Secondary cold-tightening, hot-tightening temperature |

| 250~350 | Operating temperature | – |

| >350 | 350 | Operating temperature |

| -70~-29 | Operating temperature | – |

| <-70 | -70 | Operating temperature |

Note: If the working temperature is between -29~250℃, hot-tightening and cold-tightening are not required.

2 Hot tightening or cold tightening should be carried out after the temperature of the equipment and pipeline is stable, and explosion-proof tools should be used. During the tightening period, operations such as temperature increase and pressure increase should not be performed.

3 When tightening, it is recommended to start from the largest flange clearance and tighten symmetrically. If there is a leak, tighten it from the leak first.

4 During the heating process of equipment and pipelines, it is necessary to check the tightening quality. Use a torque wrench at 100% torque value or use an explosion-proof hammer tool to hammer the nut in the tightening direction to check whether it is loose.

Summarize

The tightening of flange bolts is the key to ensuring the safety of pipeline connections. Correctly tightening and disassembling flange bolts can improve work efficiency and reduce economic losses. The best tools for flange bolt tightening are hydraulic wrenches and bolt tensioners, which can ensure a constant torque output and allow the bolts to accurately reach the optimal torque value. If you are working on a flange connection project, please contact us for bolting solutions.