What Is Hydraulic Pump Unloading?

Unloading means the pressure becomes zero and the oil returns to the tank. Generally speaking, it is the working state of the hydraulic system without load. That is, the pressure oil output by the hydraulic pump is directly returned to the oil tank.

Because in the hydraulic system, as long as the motor (or other prime mover) rotates, the oil pump will release oil, but the load does not move and does not need pressure oil, so the oil from the oil pump has nowhere to go, and can only return through the relief valve to the fuel tank. In this case, the heat generation is very large, and the continuous high pressure damages the oil pump and hydraulic valve. At this time, the hydraulic oil must be released back to the tank without pressure. This action is called unloading.

Therefore, the unloading state of the hydraulic system refers to the state in which the hydraulic pump continues to operate, the actuator does not act, and the relief valve has no high-pressure relief.

In the unloaded state, the actuator does not do external work, so we hope that in this state, the power consumed by the motor or the internal combustion engine that drives the hydraulic pump to run is as small as possible.

Unloading Method Of Hydraulic System

1. In a single-actuator system or a system equipped with a multi-way valve, we can use the centre machine of the reversing valve to directly unload the load.

2. Use electromagnetic relief valve to unload;

3. The electromagnetic reversing valve is used for unloading;

4. Use constant pressure variable pump to unload;

5. The unloading valve is used for unloading;

We only talk about the latter four today.

Unloading With Electromagnetic Relief Valve

Unloading principle: If we can directly connect the remote control port of the relief valve to the oil tank, then the main oil circuit of the relief valve will be opened, and the oil output from the hydraulic pump will return to the oil tank directly through the relief valve. , so as to realize the unloading of the whole system.

Features: This method uses an electromagnetic relief valve for unloading, which has a large flow range and is currently the most widely used unloading method.

Power loss calculation: Under normal circumstances, the unloading pressure of the relief valve at the rated flow rate is about 0.5MPa. We assume that the system flow rate is 200L/min, then the power loss caused by unloading can be calculated as follows: P loss = ( p*Q)/60=(0.5×200)/60=1.67(kW)

Summary: If the flow of the entire system is relatively large, the power loss of this part should not be underestimated.

Unloading With Electromagnetic Reversing Valve

Unloading principle: use the electromagnetic reversing valve to open the bypass to unload directly.

Features: The power loss of unloading is determined by the pressure loss of the selected electromagnetic directional valve.

Calculation of power loss: When the solenoid valve is used to open the bypass and directly unload the load, the solenoid valve selected is generally a 6-diameter valve. Although a valve with a diameter of 10 or more is used, there is no problem in principle, but it is not economical. Therefore, this determines that this unloading method can only be used in occasions with small flow.

It is found from the sample of the 6-diameter electromagnetic directional valve that the pressure loss is about 0.5MPa when the flow rate is 40L/min. The energy loss at this time is the same as when the electromagnetic relief valve is unloaded, so this unloading the load mode is only suitable for systems with a flow rate less than 40L/min. But at the same time, we also see that when the system flow is 20L/min, the pressure loss on the valve is less than 0.1MPa, which is much lower than the pressure loss on the electromagnetic relief valve of 0.5MPa, so the flow rate in the system is lower than At 40L/min, we should give priority to the method of direct unloading by opening the bypass of the electromagnetic reversing valve.

Summary: Due to the diameter of the solenoid valve, it can only be used in the occasion of small flow. When the flow is large, the amount of heat generated when the solenoid valve is unloaded.

Unloading With Constant Pressure Variable Pump

Unloading principle: In the system of constant pressure variable pump, when the set pressure of the pump is reached, the displacement of the pump will be close to zero, which can avoid overflow loss and greatly reduce the heating of the system.

Features: During the unloading process of the constant pressure variable pump, because the pump is always in a high pressure state, there is leakage and energy loss caused by mechanical friction.

Calculation of power loss: According to the sample of Rexroth A10V pump, when the system pressure is 20MPa, the volumetric efficiency is about 95%. We still assume that the flow rate of the system is 200L/min, then the total energy loss is P loss = p*Q/60 *(1-0.95)=(20×200)/60×0.05=3.33(kW)

At this time, the energy loss is also quite large, which is almost twice that of the electromagnetic relief valve unloading method.

Summary: In a high-pressure and high-temperature system, this unloading method should be used with special care.

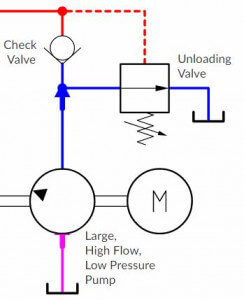

Unloading With Unloading Valve

Unloading principle: In the quantitative pump system, the structure of unloading valve and accumulator is often used to realize the unloading of the system, which has the characteristics of large instantaneous flow and long pressure holding time. When the accumulating pressure of the accumulator exceeds the set pressure of the unloading valve (actually the external control sequence valve), the unloading valve opens, and the oil output by the pump directly returns to the oil tank through the unloading valve, so as to achieve the system unloading. Purpose.

Power loss calculation: The energy loss when unloading with the unloading valve is caused by the pressure loss of the oil passing through the unloading valve. Because the structure of the relief valve and the relief valve are different, the pressure loss on the two valves is different. Generally, the pressure loss on the relief valve is only 0.2-0.3MPa, which is about 1/2 of the pressure loss of the relief valve.

Summary: This unloading method is the most energy-efficient, but at the same time its structure is the most complicated.

Summarize:

The above is a brief introduction to the four ways of unloading the hydraulic system. Each method has its own advantages and disadvantages. Different unloading methods should be used under different conditions to save energy and increase the service life of the hydraulic system. Which hydraulic pump unloading method is often used in your work? Welcome to leave a message for discussion.